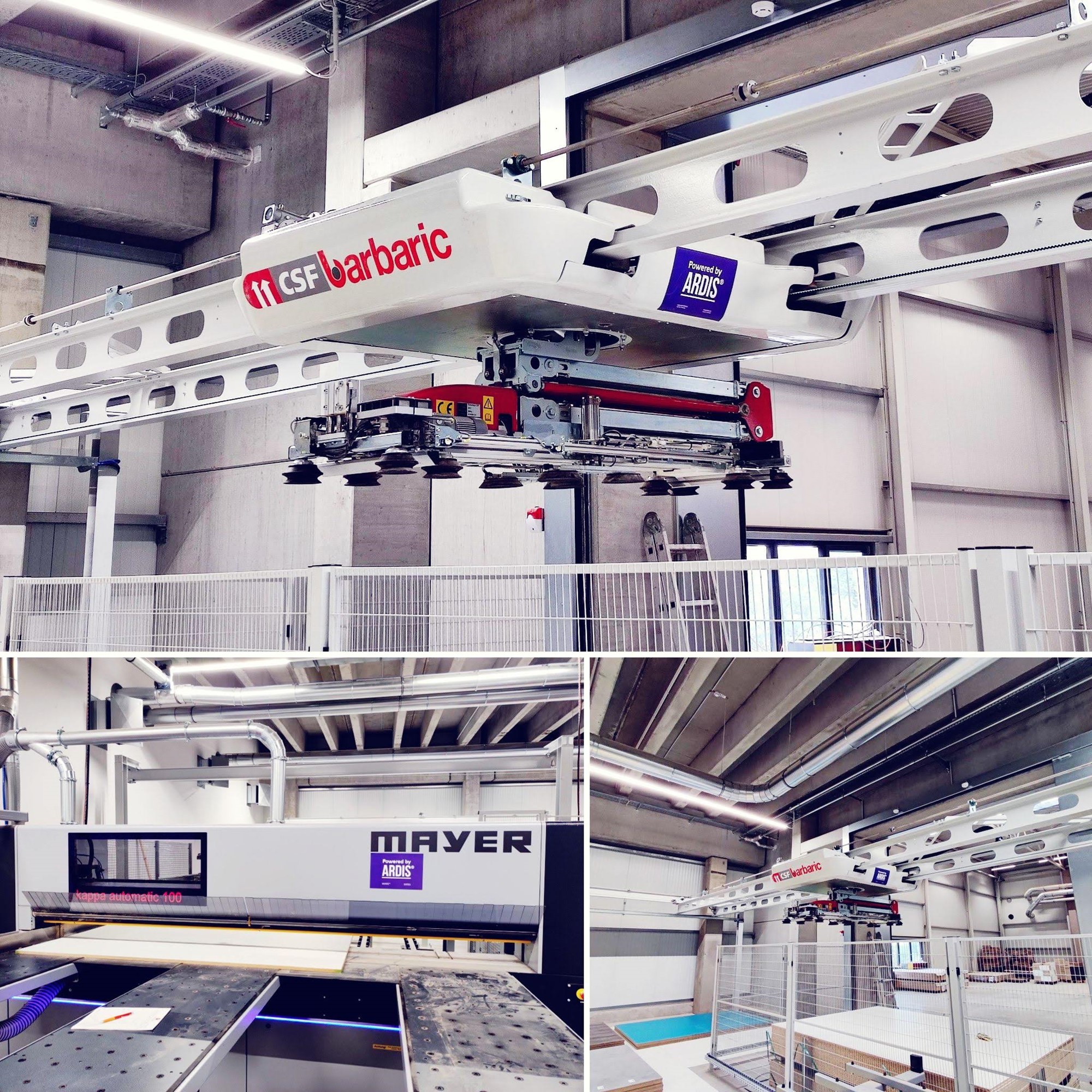

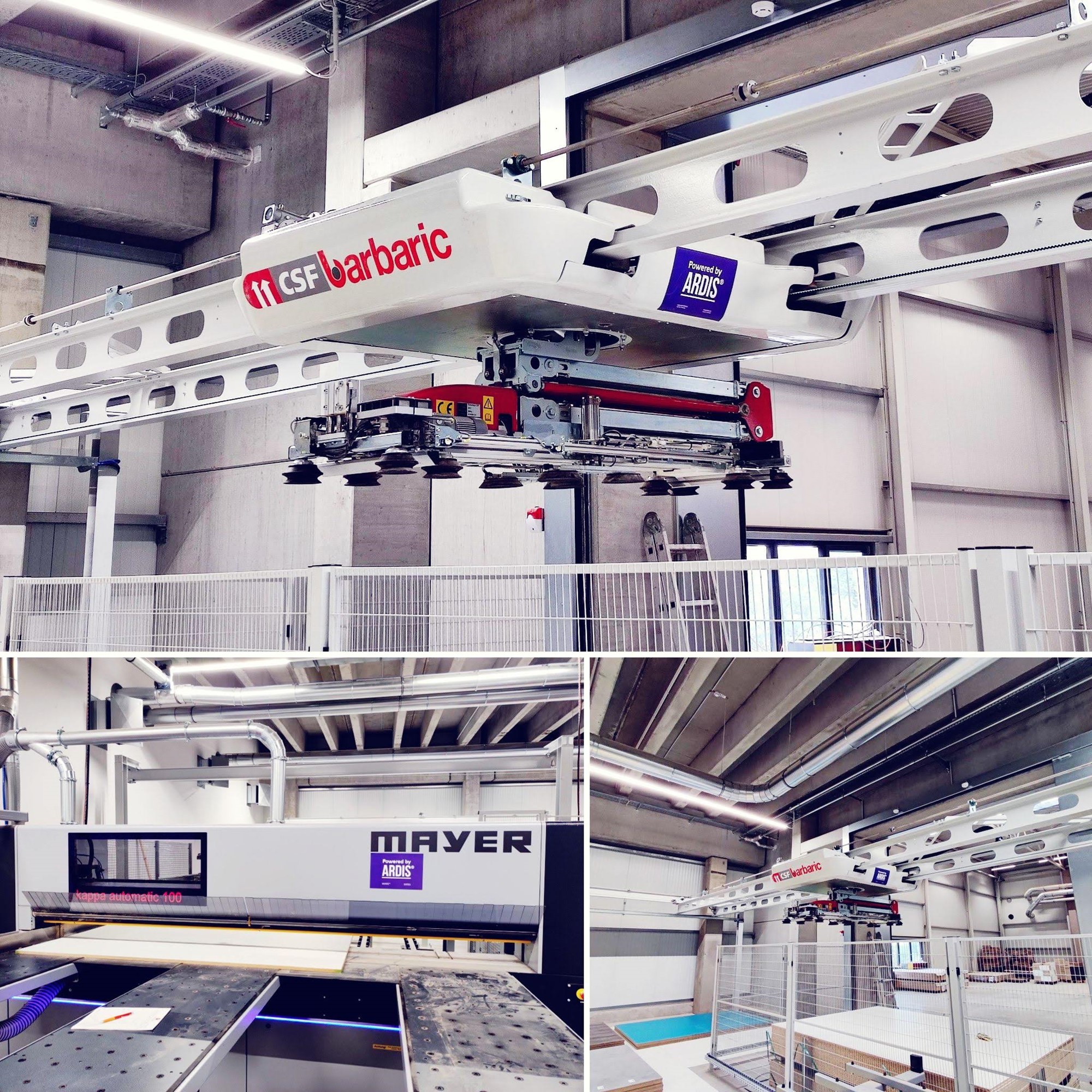

October 20, 2022 customer case Pixxprint - Pixxprint in Chemnitz (Germany) produces canvas prints, framed art prints and other wall decorations on demand. As sales orders flow in from their online shop, some of the required substrates need to be cut from larger sheets before they can go to the offset printing press. These basic material sheets are stored in a Barbaric automatic warehouse.

The Barbaric handling system picks the required sheets and applies the necessary labels on those sheets before loading them onto a Mayer Kappa Automatic 100 saw that cuts the required strips and parts. ARDIS® OPTIMIZER takes care of the entire data flow needed to control the handling system, the label printer and the beam saw.

Did you know that ARDIS® OPTIMIZER: